Professional 3D Printing Service

The introduction of Vacuum Casting

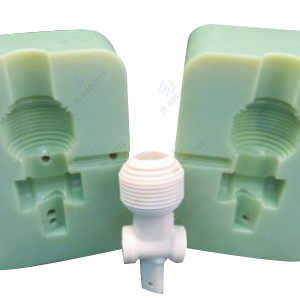

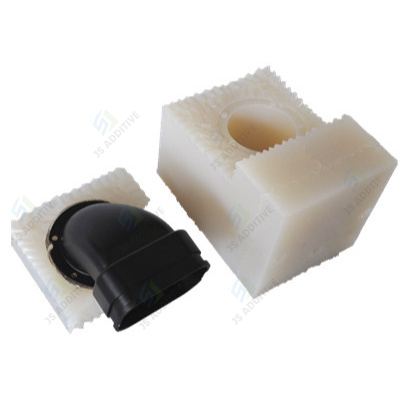

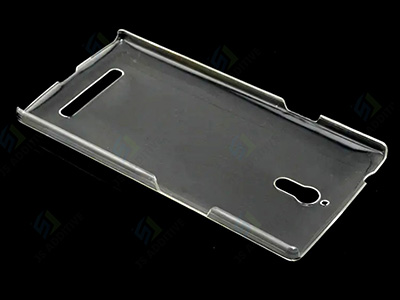

A vacuum casting apparatus which performs casting by decompression of a cavity, The vacuum casting technology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silicone mold under vacuum, and is poured under vacuum conditions, such as ABS,PU etc. Vacuum casting is also used to clone the prototype or copy the piece.

It has different types comprising: Vacuum Mould Casting, Vacuum Pressure Casting, Vacuum Sand Casting and so on. This method is especially suitable for small batch production. It is a low-cost solution to solve experimental production and small batch production in a short time, and can also meet the functional test proofing of some structurally complicated engineering samples.

Here's how it works.

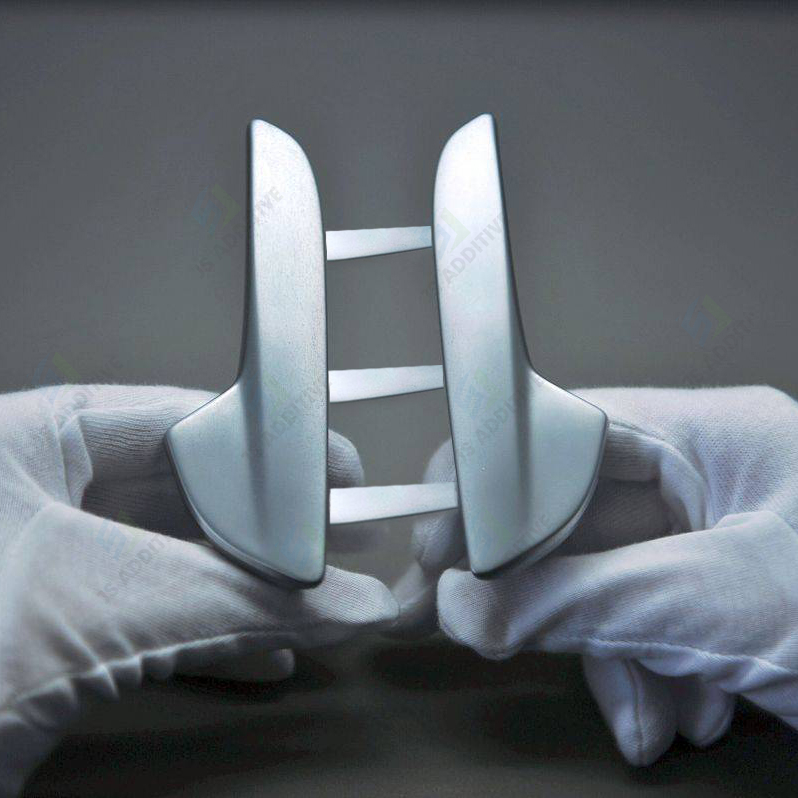

The process begins by placing a two-piece silicone mold into a vacuum chamber. The raw material is mixed with degassing and poured into molds. The gas is then evacuated to vacuum and the mold removed from the chamber. Finally, the casting is cured in an oven and the mold is removed to release the finished casting. Silicone molds can be reused. Silicone molding results in high-quality parts comparable to injection-molded components. This makes vacuum casted models especially suitable for fit and function testing, marketing purposes or a series of final parts in limited quantities.

Advantages

- The cost is low, and the product production cycle is relatively short. There is less scrap and the machining cost is much lower than CNC machining and 3D printing.

- It is suitable for the processing and production of small batches of products. After making an original version, it can be copied according to the original version. However, CNC machining requires lathes to make prototypes one by one.

- Good molding operability. The soft molds after curing and molding are all transparent or translucent, with good tensile strength, which is convenient for cutting and parting.

- The probability of processing failure is small. As long as there is no problem with the original, the replica will naturally not go wrong.

- Good repeatability. The silicone used for molding has good fluidity before curing, and with vacuum defoaming, the detailed structure and decoration of the model can be accurately maintained.

Disadvantages

- Higher initial material and manufacturing costs.

- Generally, the vacuum compound moulding prototype can only withstand high temperature of about 60 degrees, and its strength and hardness are also lower than that of the CNC prototype.

Industries with Vacuum Casting

● ABS: White, light yellow, black, red. ● PA: White, light yellow, black, blue, green. ● PC: Transparent, black. ● PP: White, black. ● POM: White, black, green, grey, yellow, red, blue, orange.

Post Processing

Since the models are printed using MJF technology, they can be easily sanded, painted, electroplated or screen printed.

Vacuum Casting Materials

For most plastic materials, here are post processing techniques that are available

| VC | Model | Type | Color | Tech | Layer thickness | Features |

|

ABS like | PX100 | / | Vacuum Casting | 0.25mm | Long pot-life Good mechanical properties |

|

ABS like-Hightemp | PX_223HT | / | Vacuum Casting | 0.25mm | Temperature resistance above 120°C Good impact and flexural resistance |

|

PP like | UP5690 | / | Vacuum Casting | 0.25mm | High impact resistance, no breakable Good flexibility |

|

POM like | Hei-Cast 8150 GB | / | Vacuum Casting | 0.25mm | High flexural modulus of elasticity High reproduction accuracy |

|

PA like | UP 6160 | / | Vacuum Casting | 0.25mm | Good thermal resistance Good reproduction accuracy |

|

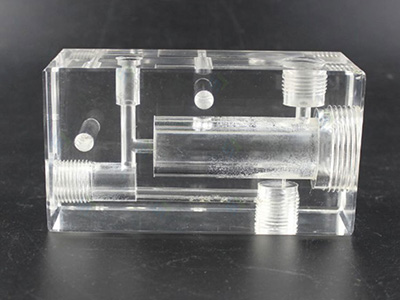

PMMA like | PX521HT | / | Vacuum Casting | 0.25mm | High transparency High reproduction accuracy |

|

Transparent PC | PX5210 | / | Vacuum Casting | 0.25mm | High transparency High reproduction accuracy |

|

TPU like | Hei-Cast 8400 | / | Vacuum Casting | 0.25mm | Hardness in the range of A10~90 High reproduction accuracy |

-

Whatsapp

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top